Understanding the Wiring Diagram for Cat5 Cable Manufactured by TMT Global Technology Ltd

Introduction to Cat5 Cable

Category 5 (Cat5) cable is a widely used standard for Ethernet networking, known for its efficiency in transmitting data. It consists of four twisted pairs of copper wire and supports data rates of up to 100 Mbps over a distance of approximately 100 meters. Cat5 cables are pivotal in enabling high-speed internet and are commonly utilized in various applications, including residential networks, business environments, and telecommunications.Wiring Diagram for Cat5 Cable

The primary purpose of Cat5 cable is to facilitate the transfer of data between devices, such as computers, routers, and switches, ensuring a reliable connection. The twisting of the pairs helps to minimize electromagnetic interference, which is crucial in maintaining the integrity of the data transmitted. Furthermore, Cat5 cables are often used in conjunction with other networking hardware, making them an essential component of modern network infrastructures.

In terms of specifications, Cat5 cabling adheres to the Electronic Industries Alliance and Telecommunications Industry Association (EIA/TIA) standards, particularly the recognized 568A and 568B wiring configurations. These standards dictate the arrangement of the wires within the cable and are essential for achieving optimal performance. Using the correct wiring diagram is vital, as improper connections can lead to reduced bandwidth, increased latency, and connection issues within the network.

With the continuous evolution of technology, Cat5 cables remain an integral part of networking despite the emergence of higher categories like Cat5e and Cat6, which offer higher performance and improved specifications. Understanding the fundamentals of Cat5 cables, including their design, applications, and the importance of wiring diagrams, is crucial for professionals and enthusiasts alike, aiming to establish efficient and reliable network connections.

Overview of TMT Global Technology Ltd

TMT Global Technology Ltd has established itself as a pivotal player in the cabling industry, particularly known for its unwavering commitment to quality and innovation. Founded with the vision of advancing connectivity solutions, the company has evolved significantly, achieving recognition for its expertise in manufacturing and distributing a wide range of cabling products. The high standards upheld by TMT Global Technology Ltd have made its products synonymous with reliability and performance.

One of the distinguishing features of TMT Global Technology Ltd is its state-of-the-art technology utilization in the production of their cabling solutions. The company integrates the latest advancements in manufacturing processes to ensure that their products not only meet but often exceed industry standards. This rigorous approach to technology ensures that their Cat5 cables, along with other products, deliver exceptional data transmission capabilities, which are critically important in today’s fast-paced digital environment.

TMT Global Technology Ltd places a strong emphasis on quality assurance throughout the production process. Each phase of the manufacturing lifecycle is meticulously monitored to uphold the integrity of the final product. This dedication to quality has fostered a reputation that resonates with both consumers and industry professionals, establishing trust in TMT’s entire product line. Their cat5 cables are particularly revered for their durability, flexibility, and adherence to international wiring standards, making them a preferred choice for various applications.

Furthermore, TMT Global Technology Ltd is dedicated to sustainability and ethical practices in its operations. The company strives to minimize environmental impact while maximizing the efficiency of its products. This holistic approach not only underscores a commitment to quality but also reflects the company’s forward-thinking ethos. Therefore, understanding the esteemed background of TMT Global Technology Ltd is crucial in appreciating the significance of their Cat5 cable and the technological advantages it presents.

Importance of Wiring Diagrams for Cat5 Cables

Wiring diagrams play a vital role in the installation and maintenance of Cat5 cables, serving as essential guides for technicians and installers. These diagrams provide a clear visual representation of the wiring layout, ensuring that each conductor is connected properly. Correct connectivity is crucial, as it determines the effectiveness and reliability of the network. When adhering to a wiring diagram, technicians can effectively prevent incorrect connections that may lead to malfunctioning systems or complete network failures.

One of the major concerns with network cabling is the potential for cross-talk, which can degrade the performance of data transmission. Cross-talk occurs when the signals from one wire interfere with those in an adjacent wire, causing a reduction in speed and clarity. Within the context of Cat5 cables, a wiring diagram ensures that the twisting of pairs is maintained according to specified standards. Following these standards creates an optimal installation that minimizes cross-talk, thus boosting the overall efficiency and reliability of the network. Moreover, by using appropriate wiring diagrams, technicians can manage the layout more effectively, mitigating environmental factors that could contribute to signal interference.

Achieving the best network speed is another significant reason for the importance of wiring diagrams. A well-organized wiring layout ensures that the data packets travel seamlessly across the network. When the wiring is configured correctly, it allows for maximum data transfer rates, thereby enhancing overall performance. In situations where Cat5 cables are laid out incorrectly, latency and connection issues may arise, leading to a frustrating experience for users. Hence, comprehensive wiring diagrams are an indispensable tool, ensuring that technicians can deliver a network that operates at its full potential.

Standard Wiring Schemes for Cat5 Cables

Cat5 cables are essential in creating robust network connections, and understanding their wiring schemes is crucial for proper installation and maintenance. The two primary standards governing the wiring of Cat5 cables are T568A and T568B. These schemes define the arrangement of the wires within the cable, impacting network performance and compatibility.

The T568A wiring scheme features a specific color-coding format where the green wire pair is placed first, followed by the orange, blue, and brown wire pairs. This method is often recommended for new installations and is compliant with the Telecommunications Industry Association (TIA) standards. T568A is particularly favored in residential installations and when connecting to equipment that follows this standard, ensuring a more seamless network integration.

On the other hand, the T568B wiring scheme has the orange pair as the first set of wires, with the green, blue, and brown pairs following in sequence. T568B is more frequently used in commercial applications and is the standard most often encountered in existing applications. Transitioning between these two wiring standards is feasible, but it is imperative to adhere strictly to one scheme throughout a given network to avoid connection issues.

While both standards enable effective data transmission, the choice between T568A and T568B may depend on specific factors such as existing infrastructure or particular equipment requirements. For visual guidance, wiring diagrams illustrating both T568A and T568B configurations are available, making it easier for technicians to identify the appropriate connections. Ensuring proper adherence to these wiring schemes helps network stability and efficiency.

Detailed Wiring Diagram from TMT Global Technology Ltd

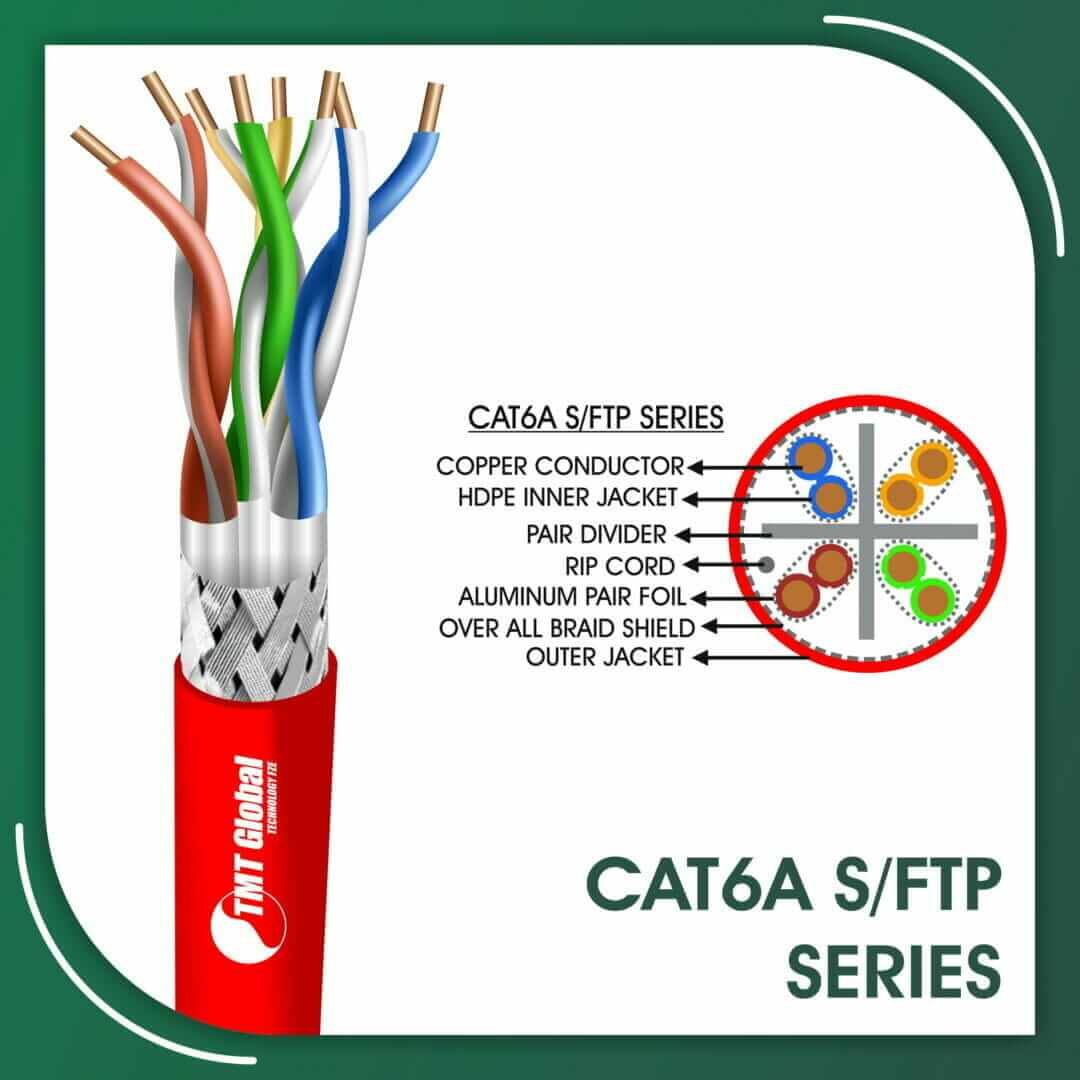

The wiring diagram for Cat5 cables produced by TMT Global Technology Ltd adheres to industry standards, ensuring reliability and performance in networking applications. A typical Cat5 cable consists of four twisted pairs of wires, each distinguished by a specific color code. The arrangement of these wires and their respective pinouts is critical for proper signal transmission.

In a standard Cat5 wiring configuration, the T568A and T568B wiring schemes are commonly used. Under the T568B standard, which is widely adopted, the color codes are as follows:

- Pin 1: White with Orange Stripes (Tx+)

- Pin 2: Orange (Tx-)

- Pin 3: White with Green Stripes (Rx+)

- Pin 4: Blue (Unused)

- Pin 5: White with Blue Stripes (Unused)

- Pin 6: Green (Rx-)

- Pin 7: White with Brown Stripes (Unused)

- Pin 8: Brown (Unused)

The significance of each wire location in the connector cannot be overstated, as it directly influences the data encoding and the overall network performance. The transmission and reception of data rely heavily on these pair configurations, wherein the twisted pairs help reduce electromagnetic interference and maintain signal integrity.

When creating or terminating Cat5 cables, it is vital to adhere strictly to these pinouts. Miswiring can result in poor connectivity, data loss, or complete network failure. Additionally, maintaining proper cable length and avoiding bends or kinks during installation is fundamental to ensuring optimal performance. A clear understanding of the wiring diagram from TMT Global Technology Ltd facilitates effective installation and troubleshooting, allowing users to leverage reliable networking capabilities for both residential and commercial purposes.

Common Mistakes in Wiring Cat5 Cables

When working with Cat5 cables, particularly those manufactured by TMT Global Technology Ltd, it is crucial to understand the common pitfalls that can lead to improperly wired connections. A frequent error is incorrect pairing of the wires. Cat5 cables are comprised of four twisted pairs, each with a specific function. Failing to adhere to the pairing standards can result in poor network performance or complete connectivity issues. It is essential to ensure that the wire colors are paired correctly according to the wiring diagram provided by the manufacturer.

Another common mistake involves the misplacement of wires within the connector. When terminating the cable, it is vital to carefully follow the color code and position the wires in the appropriate sequence. Misplaced wires can lead to signal interference or even complete failure of the communication link. Always double-check that the wires are seated correctly in the RJ-45 connector before crimping.

Furthermore, many novice technicians overlook the importance of cable length and integrity. Overly lengthy or damaged cables can lead to signal degradation. It is advisable to measure the required length precisely and inspect the cable for any physical defects before installation. The maximum length for a Cat5 cable run is 100 meters; exceeding this limit can adversely affect network performance.

To mitigate these common mistakes, it is beneficial to utilize a wiring diagram during the installation process. This visual guide serves as a reference, ensuring accurate pairing and wire placement. Moreover, employing testing tools can help verify the integrity of each cable after termination. By meticulously following the guidelines and avoiding these frequent errors, users can ensure reliable and efficient networking through Cat5 cables, thus maximizing the benefits offered by the technology.

Tools Required for Wiring Cat5 Cables

When embarking on a project involving Cat5 cables, having the right tools is crucial for ensuring a successful installation. This section will outline the essential tools you will need for wiring Cat5 cables, focusing on their specific functions and importance in the process.

To begin with, a crimper is indispensable. This tool is used to attach connectors to the ends of the Cat5 cables, allowing for seamless connections to networking devices. A high-quality crimper will ensure proper piercing of the wires and secure attachment, thereby preventing any connectivity issues. When choosing a crimper, it is important to ensure compatibility with the connectors being utilized.

Another vital tool is the cable tester. This device is used to verify the integrity and functionality of Cat5 cables after installation. A cable tester helps identify any wiring issues, such as incorrect pinouts or breaks in the cable. By employing a cable tester, users can avoid potential network disruptions caused by faulty wiring, saving both time and resources in the long run.

Additionally, cable strippers play a significant role in preparing the cables for crimping. They allow users to remove the outer insulation layer without damaging the inner wires. Properly stripped wires are essential for successful connections, making cable strippers an important inclusion in any toolkit for wiring Cat5 cables.

Other optional tools that can enhance the cabling process include a scissors for trimming excess cabling and a punch-down tool for terminating cables into wall jacks or patch panels. These tools will improve efficiency and accuracy in your Cat5 wiring projects.

In summary, having the correct tools, including crimpers, cable testers, and strippers, is fundamental for anyone working with Cat5 cables. Arm yourself with these essential devices, and you will be well-prepared to achieve optimal results in your networking endeavors.

Testing the Wired Cat5 Cable

Testing the integrity and performance of wired Cat5 cables is essential to ensure consistent network quality and reliability. Various methods are available for testing these cables, enabling users to identify any issues that may hinder performance. One of the most common tools used for this purpose is a cable tester. These devices measure the cable’s performance and verify that it has been wired correctly according to the standard pin configuration.

Cable testers generally operate in two main modes: continuity testing and performance testing. Continuity testing check for breaks or shorts in the cable by sending a signal through each wire in the cable. Users can interpret the results easily; if all wires are functioning correctly, the tester will indicate a successful test. In cases where the results show failures, the user can identify which connections might be improperly configured.

Performance testing, on the other hand, assesses the cable’s capacity to transmit data effectively under various conditions. This includes checking for parameters such as cable length, signal loss, and interference. Advanced cable testers can display performance metrics, allowing users to compare the results against industry standards for Cat5 cables. Understanding these metrics is critical for troubleshooting and ensuring that the cables perform as intended.

If issues arise during testing, several common problems could be responsible. These may include incorrect wiring, damaged connectors, or interference from external sources. Addressing these issues typically requires rechecking the wiring configuration, replacing faulty connectors, or managing the cable layout to minimize interference. By methodically testing and interpreting results, users can ensure the integrity of their wired Cat5 cables and enhance network performance effectively.

Conclusion and Best Practices

Throughout this article, we have explored the intricate details of the wiring diagram for Cat5 cables produced by TMT Global Technology Ltd. Understanding these wiring diagrams is crucial for both achieving optimal network performance and ensuring compliance with industry standards. The correctness of the installation process is paramount, as it directly impacts the efficiency and reliability of the network. Adhering to the standard pinout configurations, as outlined in the wiring diagram, will facilitate seamless data transmission and minimize potential interferences.

When installing Cat5 cables, it is essential to pay attention to the environment. Ensure that cables are protected from excessive exposure to heat, moisture, or physical damage. It is advisable to avoid running cables parallel to electrical cables, as this can induce interference. In addition, using proper connectors and maintaining cable integrity are vital steps in safeguarding against signal loss.

For future maintenance and installations, regularly inspecting the network infrastructure will help identify any potential issues before they escalate. Keeping the environment clean and organized, along with proper labeling of cables, can save time and effort during troubleshooting. Furthermore, proper cable management, such as using raceways or cable ties, will not only enhance the physical appearance of the setup but also promote airflow and reduce the risk of overheating.

In conclusion, mastering the wiring diagrams alongside implementing best practices will ensure the longevity and resiliency of network installations. By taking the time to understand the specifications and recommendations set by TMT Global Technology Ltd, one can achieve a network that meets both current demands and accommodates future enhancements. Consistently applying these practices will lead to robust networking solutions that stand the test of time.