Showing 1–20 of 113 results

Show

20

Aqua

Black

Blue

Green

Grey

Orange

Red

violet

White

Yellow

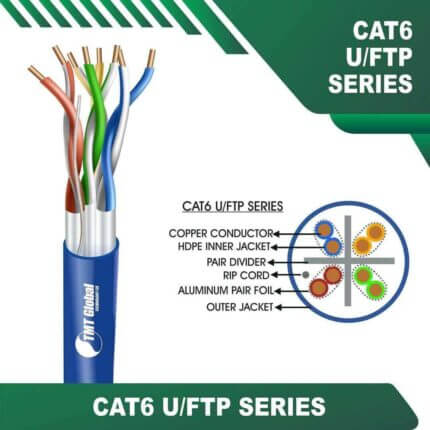

23awg cat6 4 twisted pair U FTP Network Cable 305m

SKU:

tmt-790308

Rated 5.00 out of 5

$0.00

Aqua

Black

Blue

Green

Grey

Orange

Red

violet

White

Yellow

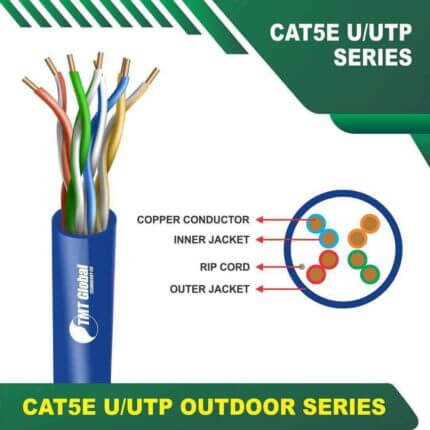

cat 5 cable color code & cat5e outdoor 24awg U/UTP Cable 305m

SKU:

tmt-790299

Rated 5.00 out of 5

$0.00

Aqua

Black

Blue

Green

Grey

Orange

Red

violet

White

Yellow

cat 6 s ftp 23awg 4 twisted pair Network Cable 305m

SKU:

tmt-790309

Rated 5.00 out of 5

$0.00

cat5e 24awg 4 twisted pair LSZH F-UTP Cable 305m 5xxx5b series

SKU:

tmt-790296

Rated 0 out of 5

$0.00

Aqua

Black

Blue

Green

Grey

Orange

Red

violet

White

Yellow

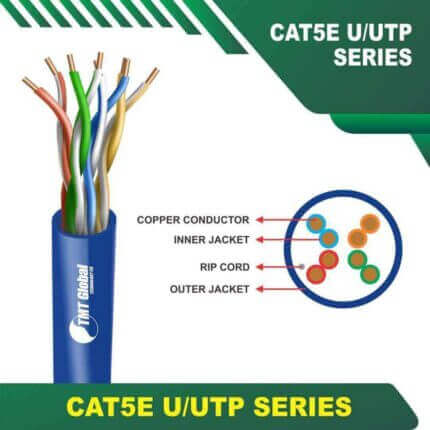

cat5e 24awg 4 twisted pair U-UTP Cable 305m

SKU:

tmt-790297

Rated 5.00 out of 5

$0.00

Aqua

Black

Blue

Green

Grey

Orange

Red

violet

White

Yellow

cat5e F UTP 24awg 4 twisted pair Cable 305m

SKU:

tmt-790298

Rated 5.00 out of 5

$0.00

Aqua

Black

Blue

Green

Grey

Orange

Red

violet

White

Yellow

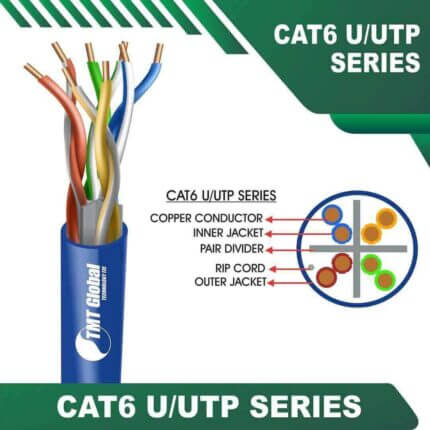

cat6 u/utp aqua ethernet cable 23 awg 4 twisted pair 305m

SKU:

tmt-790306

Rated 5.00 out of 5

$0.00

cat6 u/utp black ethernet cable 23 awg 4 twisted pair 305m

SKU:

tmt-790158

Rated 5.00 out of 5

$0.00

cat6 u/utp green ethernet cable 23 awg 4 twisted pair 305m

SKU:

tmt-790156

Rated 5.00 out of 5

$0.00

cat6 u/utp yellow ethernet cable 23 awg 4 twisted pair 305m

SKU:

tmt-790157

Rated 5.00 out of 5

$0.00

Aqua

Black

Blue

Green

Grey

Orange

Red

violet

White

Yellow

Cat6a 23awg 4 twisted pair F FTP Network Cable 305m

SKU:

tmt-790311

Rated 5.00 out of 5

$0.00