Understanding OM3 Fiber Optic Patch Cord: A Comprehensive Guide by TMT Global Technology Ltd UK

Introduction to OM3 Fiber Optic Patch Cords

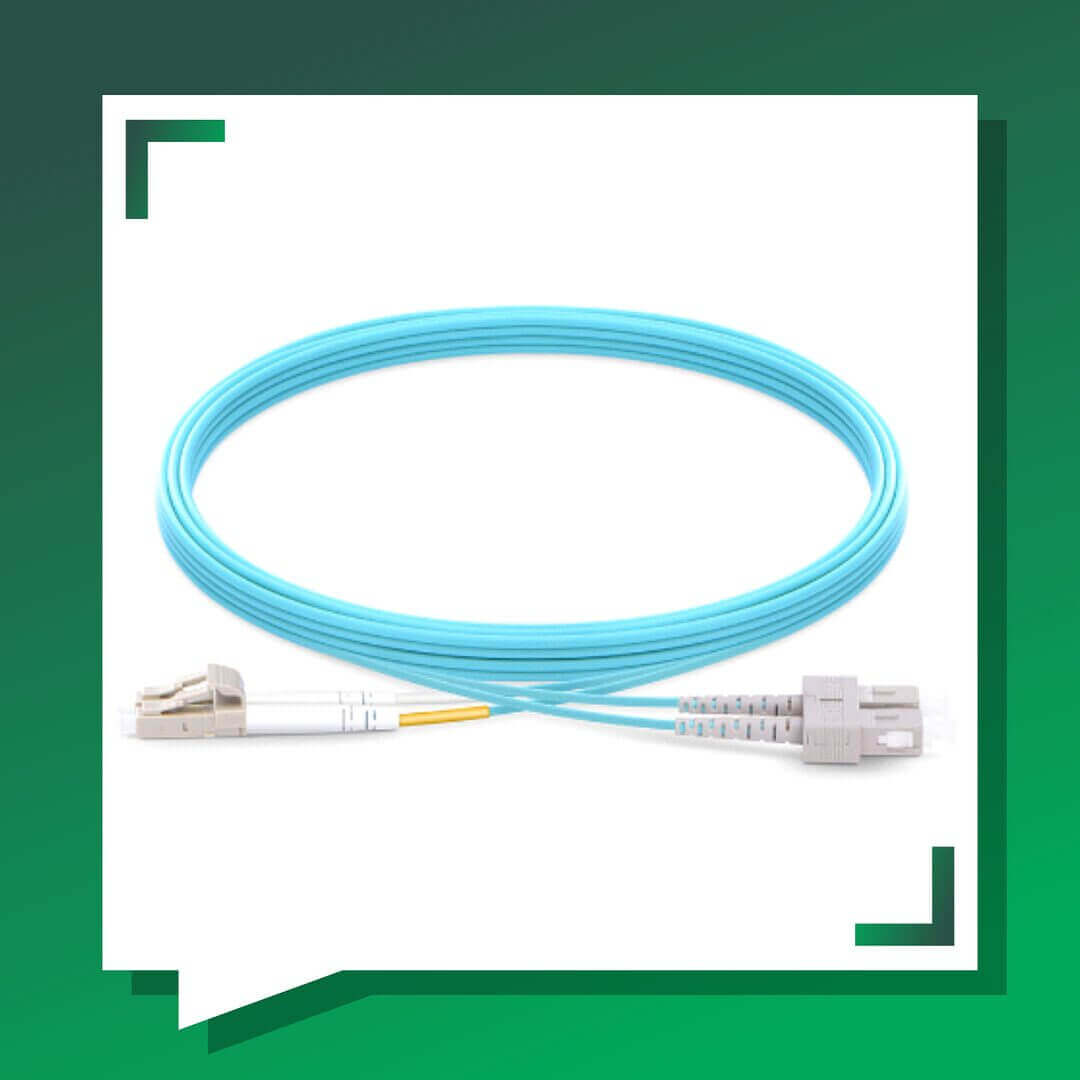

OM3 fiber optic patch cords represent a pivotal technology in contemporary communication systems, facilitating high-speed data transmission over long distances. These cords are composed of multimode optical fibers that are designed to support high bandwidth and achieve efficient performance in varied networking environments. The significance of OM3 cables lies in their ability to handle data rates of up to 10 Gbps over distances of approximately 300 meters, which makes them an ideal choice for data centers and enterprise networks.

The structure of OM3 fiber optic patch cords typically includes a core size of 50 micrometers, surrounded by a cladding layer that is designed to reflect light back into the core, thus minimizing signal loss and degradation. This construction enables OM3 cables to efficiently transmit light signals, making them particularly effective for applications such as Ethernet networking, video conferencing, and cloud computing services.

Furthermore, OM3 fiber optic patch cords are often utilized in structured cabling systems, which are crucial for establishing reliable networking infrastructures in commercial and industrial environments. Due to their high bandwidth capacities and long-distance capabilities, OM3 patch cords are increasingly favored in the telecom sector for connecting various devices within a network. Their versatility accounts for a wide array of applications, ranging from data storage systems to complex telecommunication setups.

Overall, OM3 fiber optic patch cords play a critical role in enhancing the efficiency of data transmission and are integral to the advancements seen in modern communication systems. As technology continues to evolve, the relevance of these cables in maintaining robust and speedy connectivity is expected to grow significantly.

The Manufacturing Process at TMT Global Technology Ltd

The manufacturing process of OM3 fiber optic patch cords at TMT Global Technology Ltd involves a series of meticulously coordinated steps designed to ensure the highest quality standards. Initially, the process begins with precise material selection, where TMT chooses premium optical fibers and protective jackets. These materials are pivotal as they directly influence the performance and durability of the patch cords. The optical fibers used in OM3 patch cords are specialized to maintain a balance between high bandwidth and low signal attenuation, making them ideal for high-speed data transmission.

Once the materials have been procured, the next stage is fiber splicing. This phase is critical as it involves joining two or more fiber optic cables to create a continuous pathway for light signals. TMT employs advanced fusion splicing techniques which ensure minimal loss of signal strength. Skilled technicians utilize sophisticated equipment to achieve precise alignments, reducing splice loss and enhancing the overall performance of the fiber optic patch cords.

After splicing, the cords undergo rigorous testing protocols. TMT Global Technology Ltd adheres to stringent testing standards to evaluate both the mechanical and optical performance of each patch cord. These tests typically include measuring insertion loss, return loss, and bandwidth performance to guarantee that the cords function effectively in various environments. The results of these tests are documented meticulously.

The final step in the manufacturing process is quality control, a fundamental aspect of TMT’s commitment to excellence. Each batch of OM3 fiber optic patch cords is subjected to comprehensive inspections to ensure compliance with industry benchmarks. The combined efforts in material selection, fiber splicing, and testing solidify TMT’s reputation as a manufacturer dedicated to delivering high-quality products that satisfy the demands of modern telecommunication networks.

Benefits of Using OM3 Fiber Optic Patch Cords

The transition from traditional copper cables to OM3 fiber optic patch cords presents numerous advantages, particularly in the realm of data transmission. One of the primary benefits of OM3 cables is their enhanced bandwidth capacity. While copper cables typically support a maximum bandwidth of 1 Gbps over short distances, OM3 fiber optic patch cords facilitate data rates of up to 10 Gbps over longer distances, which is crucial for modern network demands. This increased bandwidth capability enables organizations to efficiently handle large volumes of data and seamless multimedia applications.

Another significant advantage of OM3 fiber optic patch cords is their ability to transmit data over longer distances without loss of signal quality. OM3 cables can maintain effective signal integrity up to 300 meters for 10 Gbps transmissions, far surpassing the limitations of copper cables, which often require repeaters or additional hardware to cover similar distances. This characteristic not only simplifies network design but also reduces installation costs by minimizing the need for additional equipment.

In addition to their superior bandwidth and distance capabilities, OM3 fiber optic patch cords are highly resistant to electromagnetic interference (EMI). Unlike copper cables, which can be affected by electromagnetic fields and radio frequency interference, OM3 cables utilize light to transmit data, making them immune to such disruptions. This property is particularly beneficial in environments with high levels of EMI, ensuring consistent performance and reliability in data transmission.

Overall, the performance improvements offered by OM3 fiber optic patch cords over traditional copper alternatives contribute to more efficient network architecture. With advancements in digital communication requiring greater data throughput and reliability, organizations that adopt OM3 cabling solutions can expect to experience significant enhancements in their operational capabilities and future-proofing of their networks.

Applications of OM3 Fiber Optic Patch Cords

OM3 fiber optic patch cords have become indispensable in numerous sectors, due to their exceptional performance in high-speed data transfer and reliability. One of the primary applications of these cords is found within enterprise networks. Businesses are increasingly reliant on robust, high-capacity networks that facilitate efficient data communication. OM3 patch cords support 10 Gigabit Ethernet applications over distances up to 300 meters, making them ideal for large organizations that demand high throughput and minimal latency.

In the realm of data centers, the significance of OM3 fiber optic patch cords cannot be overstated. Data centers often require extensive cabling systems to connect various servers and storage devices. Here, OM3 cords contribute to the infrastructure by providing the required bandwidth for cloud services, virtualized environments, and other high-data-demand applications. Their ability to support multiple simultaneous data streams enhances operational efficiency and promotes seamless information exchange, which is crucial in today’s data-centric world.

The telecommunication industry also benefits greatly from the implementation of OM3 fiber patch cords. These cords facilitate high-speed internet connections and are essential for modern telecommunication infrastructure. By deploying OM3 patch cords, telecom providers can offer reliable and high-quality services to their customers, ensuring that voice, video, and data services operate smoothly. Furthermore, the versatility of OM3 cables allows for easy scalability as demand for bandwidth continues to increase.

Lastly, educational institutions are turning to OM3 fiber optic patch cords to enhance their networking capabilities. Schools and universities leverage fiber optics to provide students and staff with access to high-speed internet and advanced learning tools. By integrating OM3 patch cords into their systems, these institutions not only support educational growth through improved connectivity but also prepare students for a future where digital literacy is paramount.

Technical Specifications and Standards

OM3 fiber optic patch cords are pivotal in ensuring efficient data transmission in various telecommunications and networking applications. As per the standards established by the Telecommunications Industry Association (TIA) and International Electrotechnical Commission (IEC), OM3 fiber optic patch cords are designed to meet specific technical specifications that govern their performance.

The wavelength of OM3 fibers is primarily optimized for use at 850 nanometers, which is essential for standard multimode applications. One of the critical performance metrics associated with OM3 patch cords is their attenuation loss. According to industry standards, OM3 patch cords have a maximum allowable attenuation of 3.5 dB/km at 850 nm, ensuring minimal signal loss during transmission. This characteristic is vital for maintaining signal integrity, especially over longer distances.

Bandwidth capability is another crucial specification for OM3 patch cords. They are rated for 2000 MHz·km at 850 nm, which allows them to support high-speed data transmission effectively. This bandwidth is sufficient for a range of applications, including data centers and enterprise networks, where high data rates are essential.

OM3 fiber patch cords typically use LC, SC, or ST connectors, which are widely recognized in the industry for their reliability and efficiency. The choice of connector influences factors such as mating loss and compatibility with existing optical systems. It is important to note that the use of these connectors should be in accordance with existing infrastructure to ensure optimal performance.

In conclusion, OM3 fiber optic patch cords, with their defined technical specifications and adherence to industry standards, serve as an indispensable component in modern networking. Understanding these specifications can assist organizations in selecting the most suitable cable for their specific needs, thereby enhancing network reliability and performance.

Choosing the Right OM3 Fiber Optic Patch Cord

When selecting the appropriate OM3 fiber optic patch cord, several essential considerations come into play to ensure compatibility and optimal performance. One of the primary factors to assess is the length of the patch cord. It is crucial to measure the distance between the devices that will be connected, as fiber optic cables are available in various lengths, ranging from a few centimeters to several meters. Choosing a length that adequately suits your infrastructure while minimizing excess cable is vital for maintaining signal integrity and avoiding clutter.

Another critical aspect is connector compatibility. OM3 fiber optic patch cords are available with various connector types, such as LC, SC, and ST. It is essential to ascertain which connectors are compatible with your existing equipment to ensure seamless connectivity. If your devices require multiple connector types, it may be worth considering adapters for added flexibility in patch cord selection.

Environmental ratings also play a significant role in determining the suitable OM3 fiber optic patch cord for particular installations. For instance, if the patch cord will be deployed in outdoor settings or areas with stringent environmental conditions, selecting a cord with proper insulation and weatherproof ratings is vital. Indoor applications typically require less stringent specifications, but cables should still comply with standards for fire safety and low smoke emission.

Lastly, budgetary factors should influence your decision. While it may be tempting to opt for the lowest-priced option, investing in high-quality OM3 fiber optic patch cords can yield better performance and longevity, ultimately providing better value for your network over time. Therefore, balancing quality and cost is essential when making your selection, ensuring a reliable and efficient installation that meets your needs.

Installation and Maintenance Tips

Ensuring the optimal performance and longevity of OM3 fiber optic patch cords begins with proper installation and diligent maintenance. When setting up your fiber optic network, it is essential to avoid placing any undue physical stress on the cables. This can be achieved by using appropriate installations practices, such as maintaining a minimum bend radius. Fiber optic cables are susceptible to performance degradation if sharply bent, so curved pathways or appropriate cable management solutions should be employed to mitigate this risk.

Proper handling techniques are critical during installation. Always handle fiber optic patch cords by the connector, never by the cable itself, to prevent any strain that could cause internal damage. Additionally, ensure that connectors are kept clean and free from dust or other contaminants. Using lint-free wipes and specialized cleaning solutions can effectively remove any particles that may affect performance. When connecting patch cords, ensure that they are securely fitted into their respective ports to establish a reliable connection.

Periodic testing and inspections are also vital to maintaining the performance of OM3 fiber optic patch cords. Implementing regular checks can help identify potential issues before they escalate, ensuring that the network can operate at peak efficiency. Utilize optical power meters and light source testing to measure signal loss and verify that the network is functioning correctly. Moreover, it is beneficial to examine the physical condition of the cables for any signs of wear or damage during routine audits.

By incorporating these installation and maintenance practices, users can significantly enhance the reliability and lifespan of their OM3 fiber optic patch cords, ultimately leading to a better-performing network infrastructure.

Future Trends in Fiber Optic Technology

The landscape of fiber optic technology is continually evolving, driven by an increasing demand for higher bandwidth and faster communication speeds. One of the prominent trends currently observed is the shift towards higher-performance cables, particularly OM4 and OM5, which offer improved bandwidth capabilities compared to their predecessors. As network demands increase, the industry recognizes the necessity for solutions that can support data-intensive applications, such as cloud computing and high-definition video streaming. This transition signifies a concerted effort to future-proof infrastructure and optimize performance in various environments.

The advent of emerging technologies, particularly 5G, presents both opportunities and challenges for fiber optic technology. As mobile networks transition to faster standards, the need for robust and reliable fiber connections becomes paramount. OM3 fiber, once a leading standard, now contends with the need to adapt to the performance demands of 5G networks. This technology evolution requires not only advancements in material and design but also a comprehensive understanding of how these cables can be integrated effectively into existing infrastructure.

Moreover, enhancements in fiber optic manufacturing techniques are making cables lighter and more flexible without compromising on performance. This is increasingly important as installations often require navigating complex environments, such as densely populated cities or modern buildings with tight spaces. Coupled with this trend is the incorporation of smart technology in fiber optic systems, which allows for real-time monitoring and diagnostics, further improving reliability and reducing downtime. Overall, as the industry progresses, the focus will remain on creating more efficient, scalable, and resilient fiber optic solutions to meet the burgeoning demands of the digital age.

Conclusion

As we delve into the world of OM3 fiber optic patch cords, it becomes evident that choosing the right partner in this field is crucial for achieving optimal performance. TMT Global Technology Ltd stands out as a reliable choice for various reasons. Throughout this blog post, we explored the specifications, advantages, and performance metrics of OM3 fiber optic patch cords, highlighting their roles in contributing to high-bandwidth network solutions.

TMT Global Technology Ltd is committed to quality, ensuring that each patch cord adheres to stringent industry standards. The reliability of these products is vital for users who rely on fiber optic technology for effective data transmission. TMT employs advanced manufacturing techniques, which not only enhance the durability of their patch cords but also ensure that they deliver consistent performance over time. This innovative approach is integral to maintaining an edge in an ever-evolving technological landscape.

Furthermore, customer satisfaction is at the core of TMT Global Technology Ltd’s operations. With a dedicated support team, they provide timely assistance and insights tailored to meet the unique requirements of each client. This level of commitment fosters long-term relationships and builds trust among users. By consistently exceeding customer expectations, TMT establishes itself as a leader in the fiber optic industry.

In summary, TMT Global Technology Ltd is a trusted partner for OM3 fiber optic patch cords due to its unwavering focus on quality, innovation, and customer service. The comprehensive solutions offered by TMT ensure that clients can rely on high-performance fiber optic products for their networking needs, solidifying the company’s reputation within the industry. Choosing TMT means investing in the future of robust and efficient communication infrastructures.